High Output Aluminium Shavings Block Making Press Machine

$60000-65000 /Set/Sets

| Momo utu: | T/T |

| Kupu Whakauru: | FOB,CFR,CIF,EXW |

| Min. Whakatau: | 1 Set/Sets |

| Nga waka: | Ocean |

| Tauranga: | Shanghai |

$60000-65000 /Set/Sets

| Momo utu: | T/T |

| Kupu Whakauru: | FOB,CFR,CIF,EXW |

| Min. Whakatau: | 1 Set/Sets |

| Nga waka: | Ocean |

| Tauranga: | Shanghai |

Tauira No.: YS15-67-323

Waitohu: Zhouzhuang

Te Takenga Mai: Haina, Jiangstu, Haina

Mana: Hou

Te Tirotirohanga O Te Wheketere Ataata: Whakaratohia

Te Ripoata Whakamatautau Miihini: Whakaratohia

Momo Tauhokohoko: Hua Tuturu

Wā Whakamana Kōkiri: 1 Tau

Te Wa Whakamana: 1 Tau

Ratonga Waho-kore: Tautoko hangarau ataata, Tautoko aipurangi, Nga waahanga waatea, Te whakatika i te mara me te ratonga whakatika

Āhua: ISO9001: 2008

Mahi: Plc aunoa / ā-ringa

Āhuatanga: Hou

Kupu Taurangi: Kotahi tau

Tae: Ka hiahia koe

Whakamahinga: Aluminum Chips

Press Force: 3150kn (315ton)

Machine Weight: About 19ton

Work Efficiency: about 5 Blocks/Minute

Motor Power: 30+37kw

Shift Efficiency: 12.8-16ton/Shift (8 Hours)

| Hoko Hoko | : | Set/Sets |

| Momo Momo | : | nude packing |

| Tauira Pikitia | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

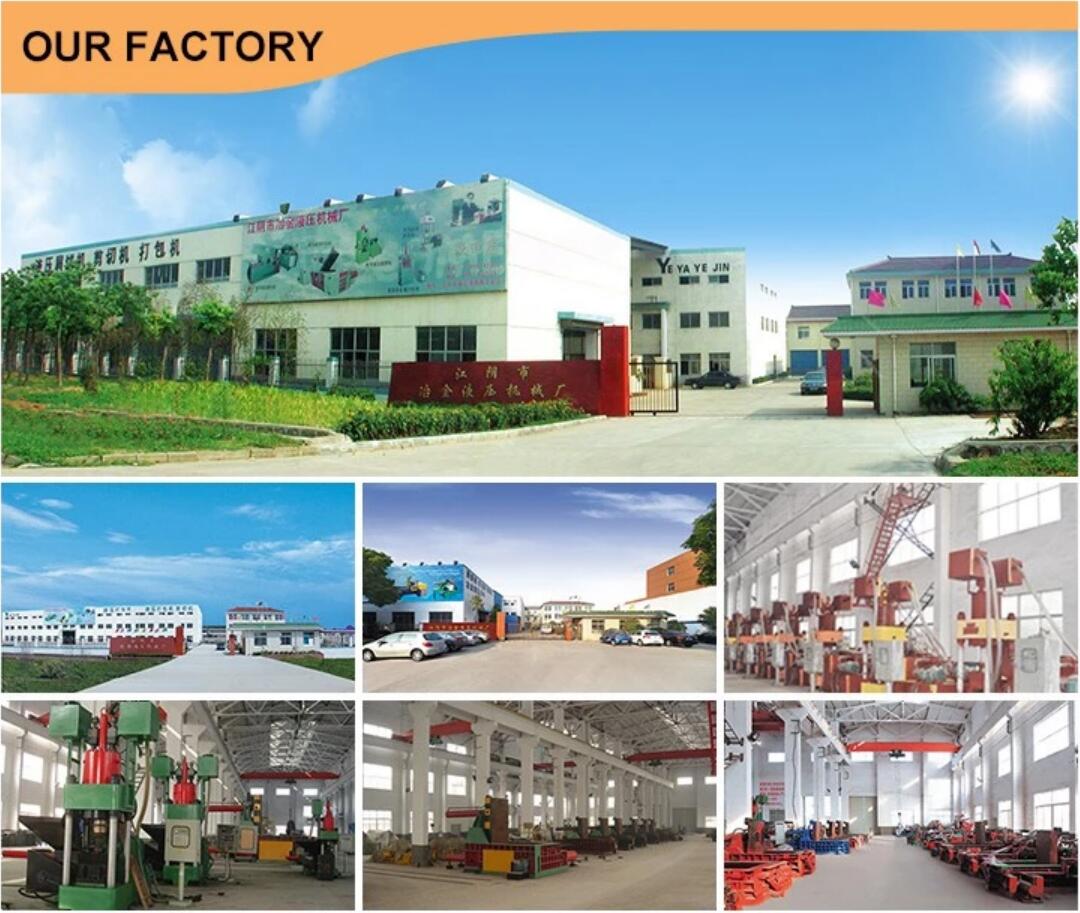

Jiangyin Metallurgy Hydraulic Machinery Factory (Chinese pronunciation: Jiangyin Yejin Yeya), brand name : ECOHYDRAULIC, was originally set up in 1989 to manufacture and sell metal briquetting press, metal balers, alligator shears, metal shears and other non ferrous scrap metal processing equipment. During the last three decades we have installed over 3000 systems , built the entire quality controlling standard and cultivated an experienced technique & after sales team. Our products are not only popular in China, but also have market shares in more than 50 Countries, for example, USA, France, India, Russia, Ukraine, Japan, Thailand, Kuwait, Vietnam, Indonesia, Canada and Columbia, etc.

Currently, we have two plants, the machining plant and the assembling plant, cover an area of 12000 square meters. There are more than 50 staff members, 7 professionals among them. And we have obtained 12 patents so far.

aluminum shavings briquette machine factory

What is a briquette machine?

A briquette recycling machine, or a briquetting press, turns waste material into uniform-sized briquettes that are easy to store and, in many cases, can be sold to generate revenue. You can make your waste problems, literally, a much smaller part of your business, and can improve your bottom line by reducing storage and handling costs and increasing income at the same time.

We have special customized horizontal aluminum chips briquette making machine with high output. This machine can squeeze valve from yours scraps waste, compress your chips into dense briquettes, separate fluids used in the metalworking process from scrap metals.

To get used to this machine, your aluminum chips should have good liquidity. Great news, we happened to have this model in stock.

YS series aluminum briquette machine is used for aluminum recycling, specially for large manufacturer and recycling center, with integrated feeding system and briquetting system, it has advantages as follows:

1) dual mode discharge structure, capacity 1.8t/h.

2) screw discharging structure, 5 briquettes per minute.

3) fully closed structure for safety operation.

aluminum chips briquette machine parameters

|

Model |

YS15-67-323 |

|

Nominal force (kn) |

3150 |

|

Briquette diameter (mm) |

Φ180 |

|

Briquette density (t/m3) |

≥2

|

|

Briquette weight (kg) |

5.5~7 |

|

Productivity (block/min) |

5 |

|

Output in one shift (t/8h) |

12.8~16 |

|

Total power (kw) |

30+37 |

|

Machine weight (t) |

19 |

|

Dimension (mm) |

4500*3000*4000 |

aluminum press team

1) Free product documents translation into your language, worry-free to operate and maintain.

2) Engineers available to service machinery overseas.

3) Customer datebase with all customers' records in it.

4) 7*24 technical phone service.

5) One year guarantee and lifelong maintenance.

6) Spare parts: Supply one set of spare parts for free, tool box, operation book.

aluminium briquette machine shipment

Packaging detail: Multiple protection methods in order to lower risks during delivery process, normally nude packing.

Shipping detail: 30 days.

FAQ for Aluminum briquetter

1) Are you a factory or a trade company?

We are manufacturer with own factory for more than 30 years.

2) How can I trust your company?

A. With professional design and sales team, we can serve you the perfect solution with lowest cost.

B. Assessed by third party, national patents for all equipment.

C. Welcome to inspect any time, we are near Shanghai airport.

D. About the machine, we are the first manufacturer of vertical briquette machine, hydraulic balers, alligator shears, shredders are also our main products.

3) Is your price competitive?

Surely we will give you best factory price based on superior product and service.

Contact us! We would like to tell you more about our horizontal aluminum briquette machine with double discharge holes

Tauākī Tūmataitinga: He mea tino nui to maatauranga ki a matou. He kupu nui to maatau kamupene kia kaua e whakaatu i o korero whaiaro ki tetahi atu whakaaetanga.

Whakakiia etahi atu korero kia taea ai e koe te pa ki a koe kia tere ake

Tauākī Tūmataitinga: He mea tino nui to maatauranga ki a matou. He kupu nui to maatau kamupene kia kaua e whakaatu i o korero whaiaro ki tetahi atu whakaaetanga.